nejvhodnější řešení

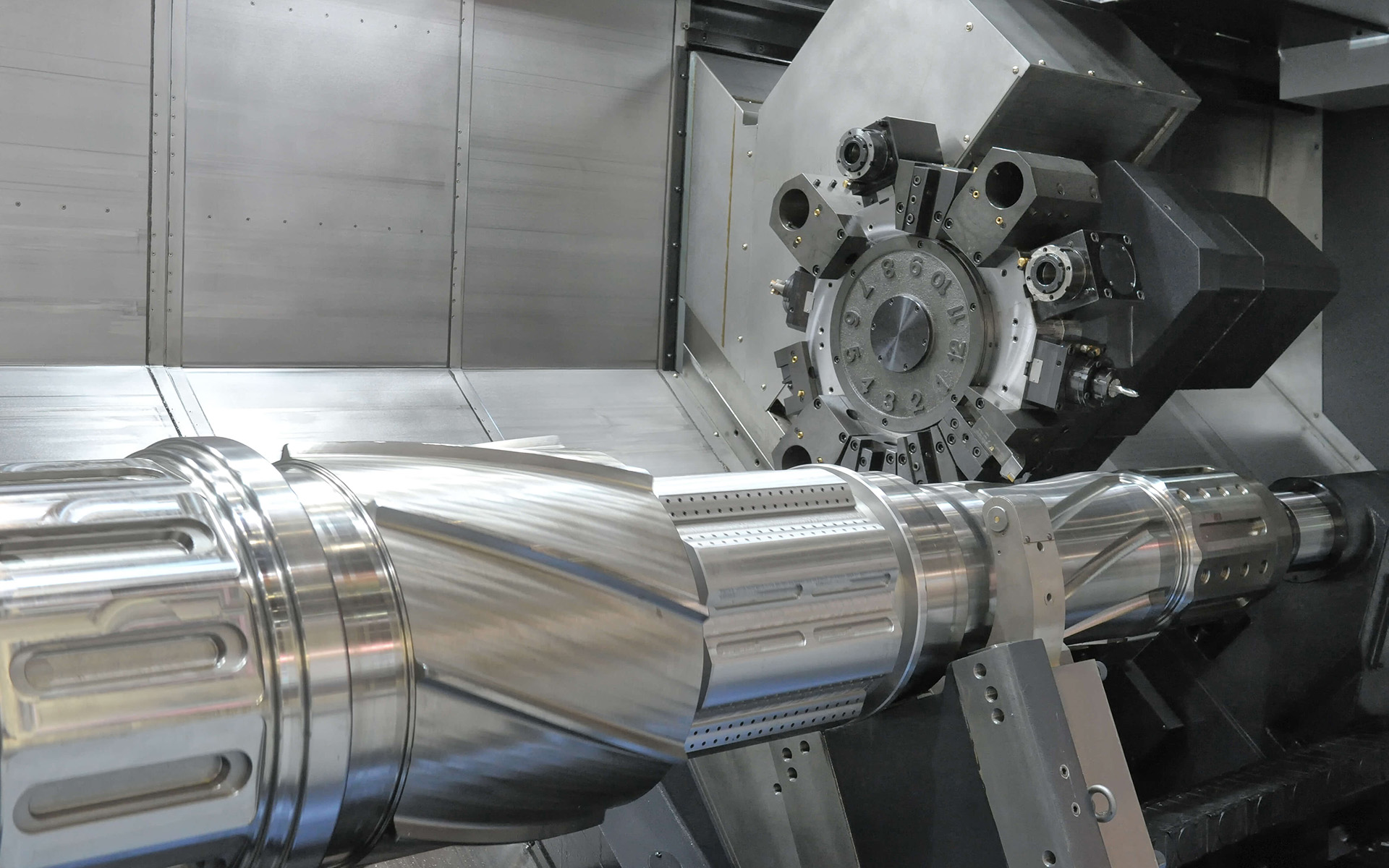

vysoká výkonnost

snadná ovladatelnost

rychlá návratnost investice

KDO JSME

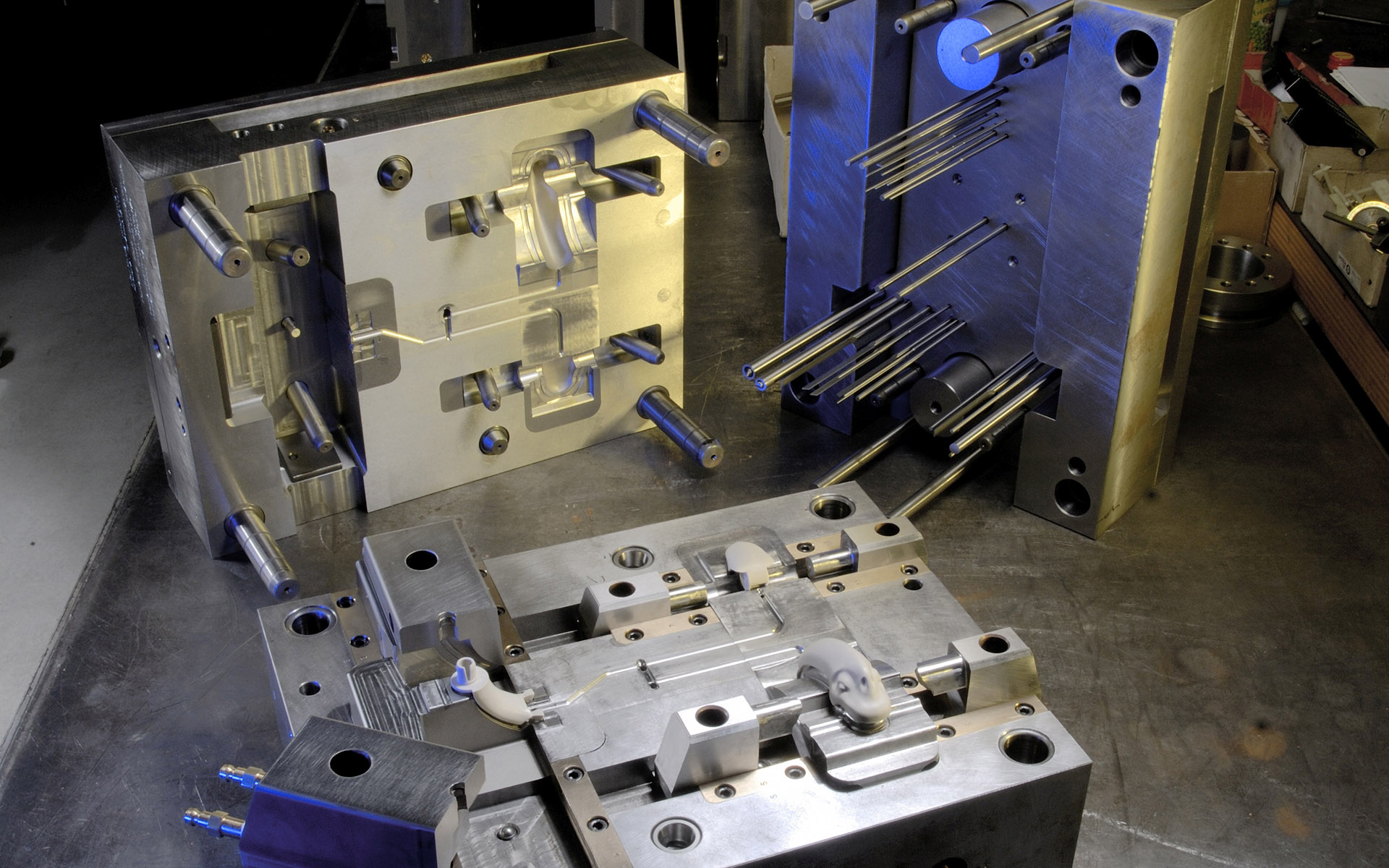

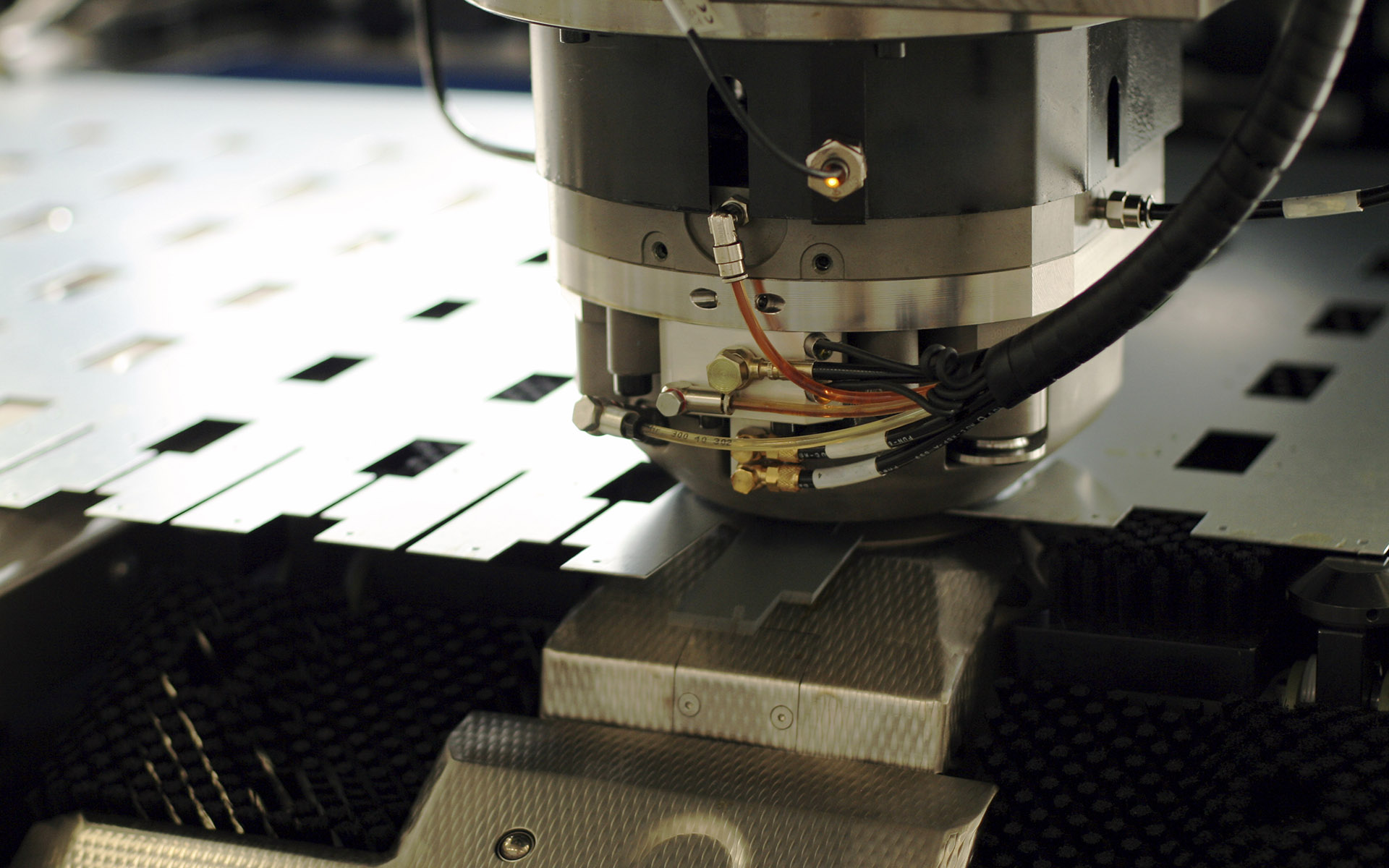

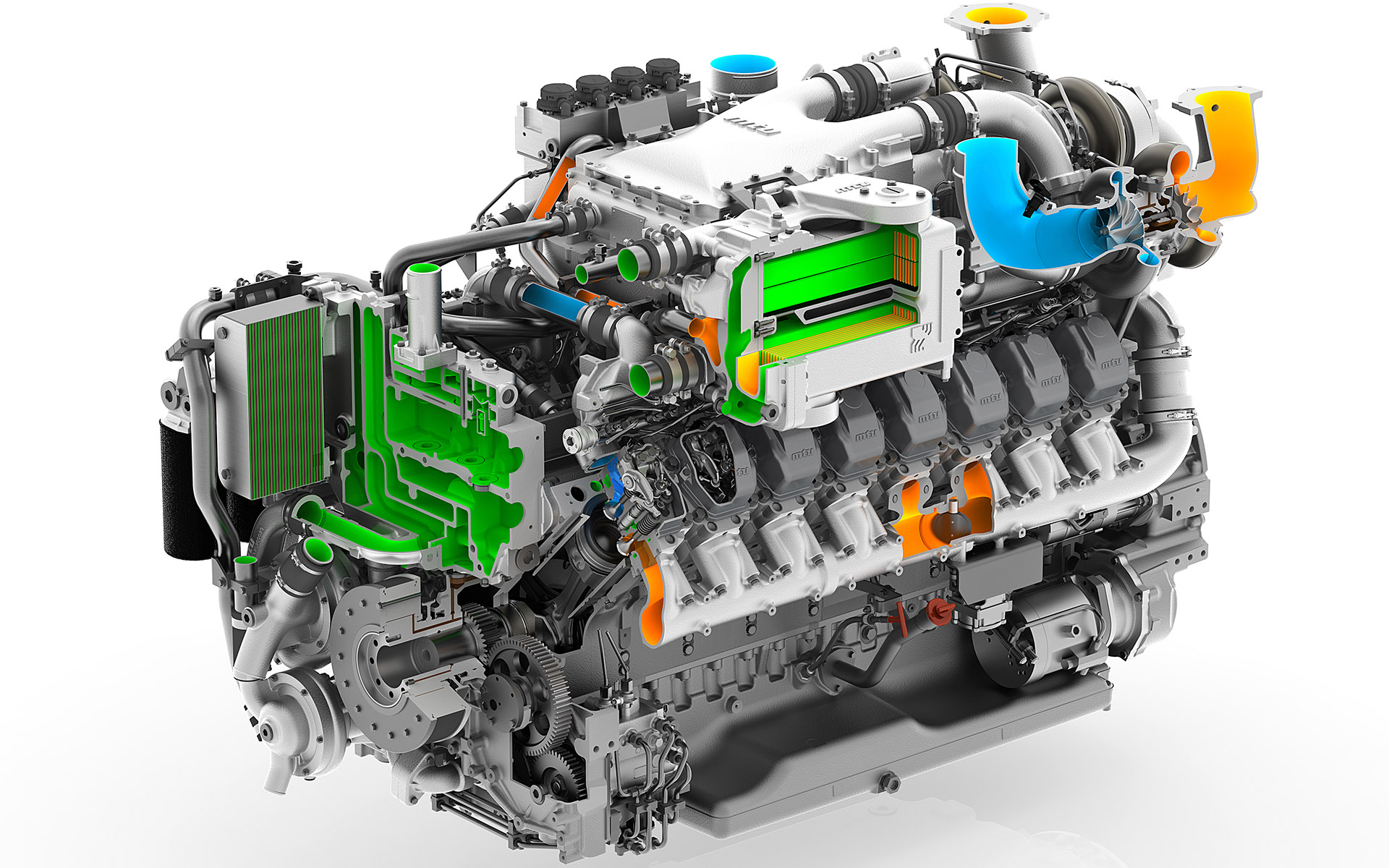

NEXNET, a.s. poskytuje služby v oblasti prodeje a technické podpory CAD/CAM aplikací a strojírenské výroby.

Nabízíme softwarové produkty společností Hexagon AB, divize Manufacturing Intelligence, ANSYS a Roboris – softwary ALPHACAM, EDGECAM, CABINET VISION, NCSIMUL, RADAN, VISI, WORKXPLORE, ANSYS Discovery SpaceClaim, SpaceClaim Engineer a Eureka. K těmto produktům zajišťujeme kompletní servis včetně lokalizace, technické podpory a školení.